...

2025-08-14 04:53

1453

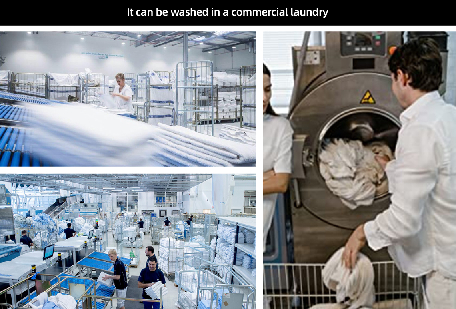

The plain towel's simplicity extends to its user-friendliness. It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details

...

2025-08-14 04:34

1946

...

2025-08-14 04:31

1561

...

2025-08-14 04:25

1380

...

2025-08-14 03:48

2478

...

2025-08-14 03:46

2142

...

2025-08-14 03:15

2050

...

2025-08-14 02:47

752

...

2025-08-14 02:41

1691

...

2025-08-14 02:40

1398

Choosing Quality Oil Seals:

Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage

Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage Mechanical seals, on the other hand, use a set of rotating and stationary components to create a seal, while labyrinth seals have multiple barriers to prevent oil leakage retainer oil seal.

retainer oil seal. It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details

It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details It requires no special instructions for washing or drying; it can be tossed in with other laundry items without worrying about colorfastness or damaging intricate details